Solar energy has already transformed how we generate power around the world. Traditional silicon solar panels now supply a growing share of electricity in countries from the United States to China and Europe. But even with cost reductions and efficiency improvements over the last decade, conventional silicon panels face physical limits that constrain their performance and how cheaply they can be made. Enter perovskite solar cells, a new class of photovoltaic (PV) technology that scientists and companies are calling a game changer for the solar industry.

While the technology is still maturing, developments through 2025 and early 2026 demonstrate perovskites’ promise to boost solar efficiency, lower manufacturing costs, and unlock applications that were once impractical. In this blog, we’ll explain what perovskite solar cells are, how they work, why they matter, the challenges they face, and what the future may hold for this “wonder material.”

What makes perovskite solar cells different

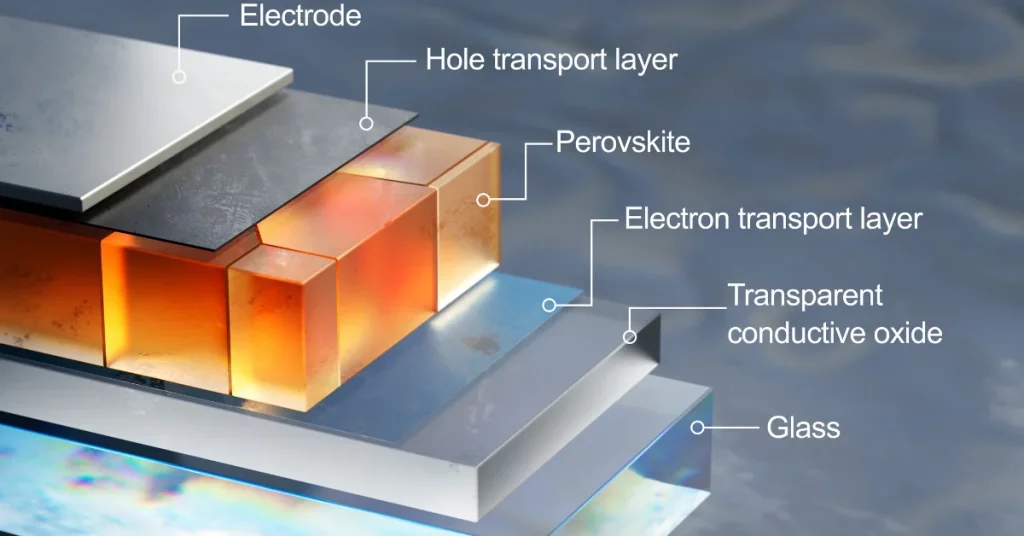

The heart of any solar cell is the material that absorbs sunlight and converts it into electricity. Traditional silicon cells, used in most of today’s solar panels, are made from crystalline silicon wafers that generate electrical current when struck by photons. Perovskite solar cells use a different kind of material with a distinctive crystal structure first discovered in the 19th century. The term “perovskite” describes a class of compounds with the same internal structure as the mineral perovskite.

In solar applications, perovskite materials are usually made from combinations of organic ions, metals, and halogens (elements like iodine, bromine, or chlorine). These metal-halide perovskites make excellent light absorbers, and their crystal arrangements allow electrons to move efficiently, a key factor for generating electricity.

Because perovskite layers can be made extremely thin (just fractions of a human hair), they can be processed at lower temperatures and with simpler manufacturing steps than silicon. This opens the possibility of producing them with much lower energy input and cost than traditional silicon modules.

Why perovskites could transform solar power

Perovskite solar cells have shown rapid progress in a relatively short span of time. In laboratory settings, single-junction perovskite devices have reached efficiencies of about 27 percent, rivaling or surpassing many silicon technologies, and when paired with silicon in a tandem configuration they can exceed 34 percent efficiency in lab tests. These tandem cells stack a perovskite layer on top of silicon, allowing each layer to capture different parts of the sunlight spectrum.

In simple terms, that means perovskite-based modules can convert more sunlight into useful power than standard solar panels of the same size, which is crucial for maximizing energy output on rooftops, built environments, and land-constrained installations.

Another advantage is manufacturing flexibility. Perovskites can be made into lightweight, thin, and even semi-transparent films that can be applied to surfaces where rigid silicon panels might be impractical. Researchers and companies are exploring applications such as building-integrated photovoltaics (solar windows), flexible solar wraps, and even solar roofs that blend seamlessly with architectural materials.

How perovskite technology has evolved

Perovskite solar cells arrived on the research scene just over a decade ago with very modest efficiencies, around 3 percent in early prototypes. Since then, scientists have made astonishing strides through advancements in material composition, interface engineering (the layers that connect perovskite to electrical contacts), and tandem designs.

As of early 2026, perovskite-silicon tandem devices are not only achieving higher efficiencies than standalone silicon panels in the lab, but companies such as Oxford PV and others have begun producing pilot shipments of tandem modules for real-world testing. These commercial pilot modules are designed to demonstrate performance outside the lab and help build confidence in long-term reliability.

National research organizations, including the U.S. Department of Energy, are actively funding development programs to improve perovskite performance, manufacturing methods, and durability while aiming to bring hybrid tandem technologies to commercial viability by 2026-27.

Challenges before broad commercial adoption

Despite the impressive progress, perovskite solar cells still face hurdles before they can fully replace or significantly supplement silicon technologies in the global market.

Stability and durability

One of the biggest challenges is long-term stability. Perovskite materials can be sensitive to heat, moisture, and ultraviolet light, which can cause degradation over time. Silicon panels, by contrast, are proven to last 25–30 years with declining performance that panel manufacturers can reliably guarantee. For perovskites, long-term field data are still being collected, and accelerated lab tests are used to estimate how the cells might age in real world conditions.

Researchers are actively developing strategies to improve stability, such as embedding nanoparticles to trap volatile elements like iodine, and creating more resilient interfaces between layers. Some experimental methods have succeeded in dramatically enhancing lifetime and reducing degradation, but real-world reliability remains a key focus for commercialization.

Environmental and material concerns

The most efficient perovskite compositions used today often contain lead, which raises environmental and safety questions for production, deployment, and recycling. While the amount of lead is small compared with many industrial products, industry and researchers are exploring ways to mitigate risk, design recycling processes, and develop lead-free perovskite variants such as tin-based alternatives that could reduce environmental impacts.

Scaling up production

Producing consistent, high-quality perovskite panels at large scale remains a manufacturing challenge. Many of the efficiency records achieved in laboratories involve small sample cells; scaling those results to full-size commercial modules without losing performance is a complex engineering task. Achieving uniform performance over large areas, a necessity for solar farms and rooftop installations, is a priority for developers and manufacturers.

Where perovskite technology could be used

Because of their potential for high efficiency and low weight, perovskite solar cells are being considered for a wide range of applications beyond traditional solar farms:

- rooftop and utility installations: tandem perovskite modules could boost energy yield in residential and commercial systems.

- building integrated photovoltaics: semi-transparent or flexible panels can be incorporated into windows, façades, or architectural surfaces.

- transport applications: lightweight designs may find use on electric vehicles or transportation infrastructure where conventional panels are too heavy or rigid.

In Japan, government investments are already backing ultra-thin perovskite solar cells that could be applied to urban structures such as stadiums and airports where space is limited. This kind of strategic national focus shows how perovskites might fit into broader clean energy goals beyond standard ground-mounted systems.

The future of perovskite solar technology

The pace of innovation in perovskite solar cells suggests that this technology could play a major role in the next generation of solar energy. As materials and manufacturing methods improve, and as scientists make progress tackling stability and environmental challenges, commercial adoption may accelerate. The combination of high efficiency, lower manufacturing costs, and design flexibility positions perovskite cells as a strong contender to complement or even outperform silicon in many applications.

Even if widespread adoption takes several more years, the rapid progress in tandem efficiency and real-world pilot deployments shows that perovskite technology has moved beyond purely theoretical research. The solar industry is already incorporating these materials into real projects, indicating a shift toward commercialization in the near future.

Concluding thoughts

Perovskite solar cells represent one of the most exciting developments in solar technology today. They combine the promise of high performance, low production costs, and design flexibility with the potential to open new uses for solar energy. While there are still significant engineering and material challenges to overcome, researchers and companies around the world are aggressively pushing the boundaries of what is possible.

As innovations continue to emerge, and as commercial trials expand, perovskite technology may well be remembered as the breakthrough that helped solar become cleaner, more efficient, and more embedded in everyday infrastructure. At the very least, it shows that the next chapter of solar power is being written today in laboratories and factories alike, and the story is far from over.

Sources:

Perovskite: The “wonder material” and solar transformation overview. (Solar Now)

Department of Energy explanation of perovskite solar cell basics. (The Department of Energy’s Energy.gov)

Nature Reviews coverage of recent perovskite advances. (Nature)

Perovskite stability research enhancements. (ScienceDaily)

Tin-based perovskite developments. (Wikipedia)

Japan’s investment in ultra-thin perovskite cells. (Financial Times)