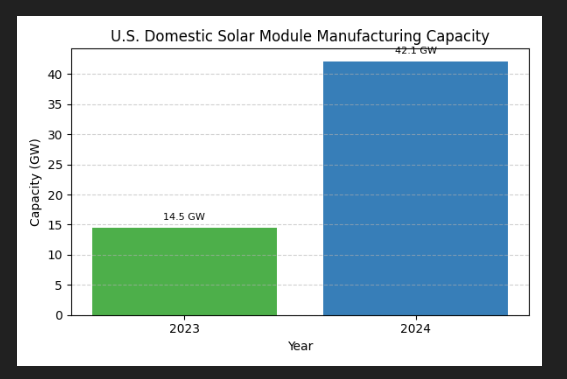

Solar Handbook – The solar market in the United States is growing very fast. In 2024 the country installed 50 GW of new solar capacity, a 21 percent increase from the year before. Domestic manufacturers also increased production from 14.5 GW in 2023 to 42.1 GW in 2024. Rapid expansion brings many opportunities but also challenges for distributors and installers who need to source quality equipment and comply with a complex regulatory framework. This solar energy handbook condenses best practices and current data into a single guide for wholesale buyers and suppliers.

Key steps for sourcing products in the wholesale market

The secondary solar market allows companies to purchase panels, inverters and other components when supply chains are tight. Following these basic steps helps reduce risk and ensure reliable partnerships:

- Use trusted exchanges. B2B exchanges such as EnergyBin vet their members and require business registration and references, reducing the chance of counterfeit goods.

- Perform due diligence. Before placing an order, review the seller’s company profile and call references to confirm experience and reliability.

- Clarify terms. Discuss product availability, warranties, minimum orders, delivery times, return policies and payment terms with the seller. This direct contact helps verify that the seller is authorized to sell the equipment.

- Confirm inventory. Ask where goods are stored and request photo proof of product labels. Insist on inspecting the first purchase or use an escrow service if prepayment is required.

By taking these steps, buyers can build long term relationships with reputable suppliers and avoid costly mistakes.

Evaluating panels and balance of system equipment

Finding the best equipment involves more than comparing prices. SolarBuilder notes that installers often mix up peak power (watts) and energy yield (kilowatt hours produced over time). The panel with the highest rating may not deliver the most energy over its life. Buyers should model expected output and ensure that inverters and other electronics are sized properly to avoid energy clipping.

Other factors to consider include:

- Module size and power density. Some manufacturers increase wattage by making larger panels, but a compact module can provide more watts per square meter and allow higher capacity on limited roof space.

- Reliability and warranty. Choosing a low cost supplier may save money up front, but long term support matters. A 25 year warranty is only valuable if the manufacturer remains in business. Look for strong financial backing and clearly written warranty terms.

- Bankability. Bloomberg’s Tier 1 list filters new suppliers but does not guarantee financing or quality. Always review the manufacturer’s track record and customer feedback.

Evaluating these aspects ensures that the system delivers energy as expected and protects the buyer’s investment.

Understanding standards and certifications

Standards ensure that products meet minimum safety and performance requirements. UL 1703 applies to flat plate photovoltaic modules used on buildings. Many local jurisdictions will not issue permits for modules without this certification. Tests measure energy output under standard conditions and simulate environmental stresses such as heat and hail.

UL 61730 has two parts.

Part 1 contains design requirements to prevent electric shock and fire.

Part 2 lists test sequences that confirm the product’s safety up to 1 500 V DC.

Other relevant certifications include:

Buyers should ask suppliers for certificates and confirm that tests were performed by a recognized laboratory. Products with additional certifications may cost more per watt but often provide better durability.

Inverters and batteries have their own certifications, such as UL 1741 for inverter safety and grid connection and UL 1973 or UL 9540 for stationary storage systems. Though this handbook focuses on modules, a complete procurement checklist should verify that every component is tested and certified.

Regulatory requirements in the United States

Several laws govern how solar products are tested, labelled and disposed of. UL and ASTM standards provide the core safety framework. ASTM E948 measures the electrical performance of photovoltaic cells, while ASTM E1830 tests mechanical integrity under wind, snow and twist loads.

Electrical devices must also comply with 47 CFR Part 15, which regulates unintentional radio frequency emissions. Manufacturers need to file a Supplier’s Declaration of Conformity and may have to test emissions.

The Resource Conservation and Recovery Act (RCRA) governs the handling of hazardous waste. As panels reach the end of their service life, suppliers and installers should partner with certified recycling facilities to ensure safe disposal.

Manufacturers and importers should maintain laboratory test reports and other documentation to show compliance with these standards. Certification bodies such as Intertek, TÜV SÜD and Eurofins can perform the required tests.

Supply chain trends and domestic manufacturing

Procurement strategies depend on supply chain conditions. The 2024 Solar Market Insight report from SEIA notes that domestic module manufacturing capacity grew by 190 percent in one year. With 42.1 GW of annual production in 2024, U.S. factories can meet most domestic demand. Increased local production reduces dependence on imports and helps stabilize prices.

A concise checklist for your solar energy handbook

When developing an internal handbook or a downloadable guide for clients, consider organizing the information into clear sections:

- Market overview. Provide recent installation data, manufacturing capacity figures and cost trends. Use authoritative sources such as SEIA.

- Supplier vetting. List steps for verifying vendors, including membership in trusted exchanges, references and financial health.

- Product evaluation. Explain the difference between rated power and energy yield, highlight factors such as module size and warranty terms and remind buyers to model long term energy production.

- Standards and certifications. Include a table summarizing UL, IEC and ISO standards with a brief description and application.

- Regulatory obligations. Summarize relevant laws, such as ASTM testing requirements, FCC emission limits and environmental regulations.

- Supply chain strategy. Discuss domestic manufacturing trends and advise on inventory planning given lead times and segment demand.

Conclusion

The rapid expansion of solar capacity and local manufacturing in the United States has created both opportunities and complexities for suppliers and installers. A well organized solar energy handbook helps companies navigate these dynamics. By using trusted exchanges, vetting vendors carefully, evaluating products beyond their wattage rating and ensuring compliance with standards and regulations, businesses can reduce risks and deliver reliable systems. Keeping an eye on domestic manufacturing capacity and market segmentation helps buyers plan inventory and pricing strategies. With the guidance provided in this handbook, distributors and installers can confidently procure equipment and meet the growing demand for clean energy.