John, a hard-working solar installer, spends half his day on the phone instead of on rooftops. Instead of focusing on wiring panels or meeting clients, he’s juggling dozens of vendors – negotiating prices, scheduling deliveries, and tracking shipments. This hidden office work eats up 10-15 hours per week, turning profitable days into endless phone marathons. He’s far from alone: many independent installers find themselves buried in paperwork and procurement logistics.

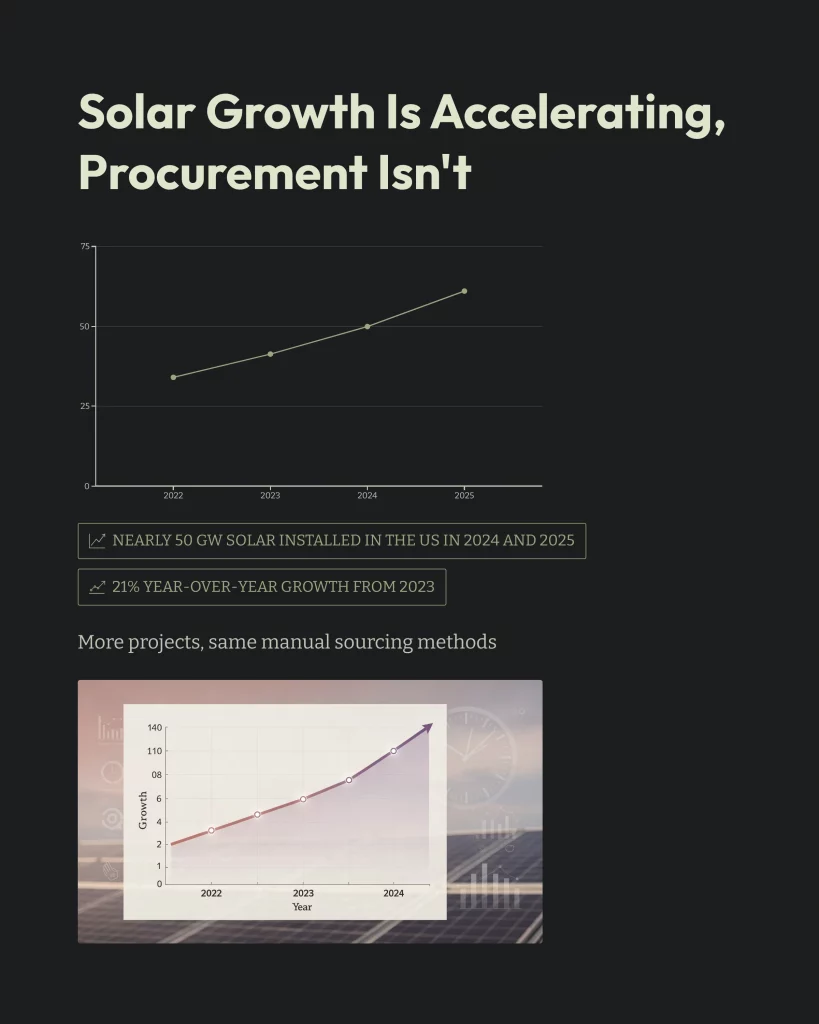

As solar adoption booms nationwide, efficient procurement becomes even more critical. The U.S. installed nearly 50 GW of new solar capacity in 2024 (a 21% increase over 2023), putting enormous pressure on supply chains. For independent contractors, this growth is great news – and a potential headache. The demand is soaring, but the old way of sourcing parts (phone calls and emails) simply can’t keep up.

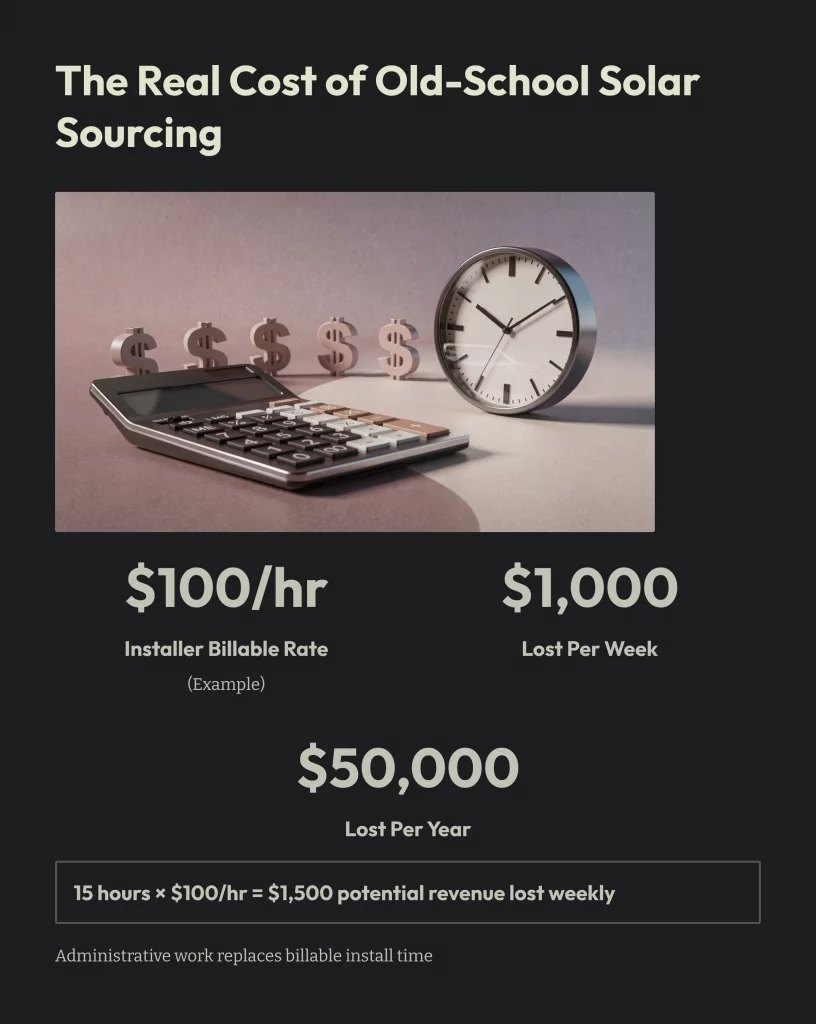

The Hidden Cost of Solar Procurement

For a small business, those lost hours quickly add up. Administrative overhead directly cuts into billable installation time. If John bills $100/hour, that’s $1,000 a week ($50K per year) slipping away on phone calls and paperwork. Over months, the cost is staggering. Industry experts note that sourcing components is surprisingly time-consuming: “it’s time consuming for solar buyers to call and email around to determine who has inventory and wait to get a quote”. Many installers lack direct contacts at manufacturers and often wait on distributors to relay stock info, creating frustrating bottlenecks.

For example, tracking down who has a specific inverter in stock might involve three calls and an email – easily 30 minutes gone per part type. Dozens of callbacks for panels, inverters, batteries and other Balance-of-System components can consume an entire workday. Each interrupted installation costs billable hours and delays project timelines, all while that sunlit afternoon is wasted on hold music instead of actual solar work.

The Fragmented Vendor Trap

Part of the problem is a fragmented supplier network. Installers like John use several distributors (e.g. Soligent, BayWa, CED) and manufacturers, each with its own catalog and process. If one supplier is out of stock or slow to respond, he must call another – wasting more time. As one analyst observes, the solar industry was “behind the times” in procurement, still having installers juggle individual suppliers. This fragmentation means more project delays and mistakes – exactly the kinds of problems that eat into time and profit.

Confusion also arises because installers think in system size (watts), but vendors quote parts in panel counts or pallet units. “Solar contractors deal with projects in Watts, but sellers list by number of panels, in bulk containers or other units”. For instance, a request for a 10 kW system (roughly 30 panels) might elicit quotes in terms of pallets (hundreds of panels), forcing extra calls just to translate units. The bottom line: traditional buying is built for large warehouses, not nimble installers – and it shows in lost time and missed opportunities.

Introducing a Virtual Project Desk

Now imagine having a dedicated virtual procurement assistant for every project. Enter Sunhub’s Source Center (a.k.a. the Custom Order Desk). Instead of spending hours on calls, John simply posts one online request with all his equipment needs (panels, inverters, mounts, batteries, etc.). Verified suppliers across the country see the RFQ and compete to offer the best price and schedule.

Sunhub markets this boldly: it calls itself “America’s #1 Solar Equipment Marketplace,” where installers “post equipment requests and receive competitive quotes” from dozens of vendors. In practice, that means John trades days of calling around for a quick form and a few clicks. Within a day or two he’s getting back multiple quotes – all without dialing a dozen numbers.

Key benefits of this centralized approach include:

- One-stop sourcing: All needed parts are listed in one place, avoiding mix-ups across vendors.

- Better pricing: Multiple suppliers bid on the same request, driving quotes down through competition.

- Massive inventory: Instantly taps into both new and used stock across the network.

- Faster fulfillment: The platform coordinates delivery logistics, so orders arrive on schedule without you chasing.

In effect, posting an RFQ on Sunhub is like having a mini-EPC on demand. You don’t need a full-time purchasing manager – the RFQ desk handles it for free. John reports that Sunhub turned hours of work into minutes of setup: within 48 hours he had quotes in hand and could compare options instantly.

So why waste time (or money on a buyer)? Let Sunhub’s Custom Order Desk handle it. Post your RFQ, review competitive bids, and pick the best deal. The result: projects stay on schedule, budgets stretch further, and installers like John get back to doing what they do best.

Stay tuned for Part 2: In our next post, we’ll walk through the RFQ process step by step (showing how to source even discontinued solar panels) and explain how installers can maximize those savings.